An Inside Look at Precision Stamping Dies for Automotive Applications

Understanding Precision Stamping Dies

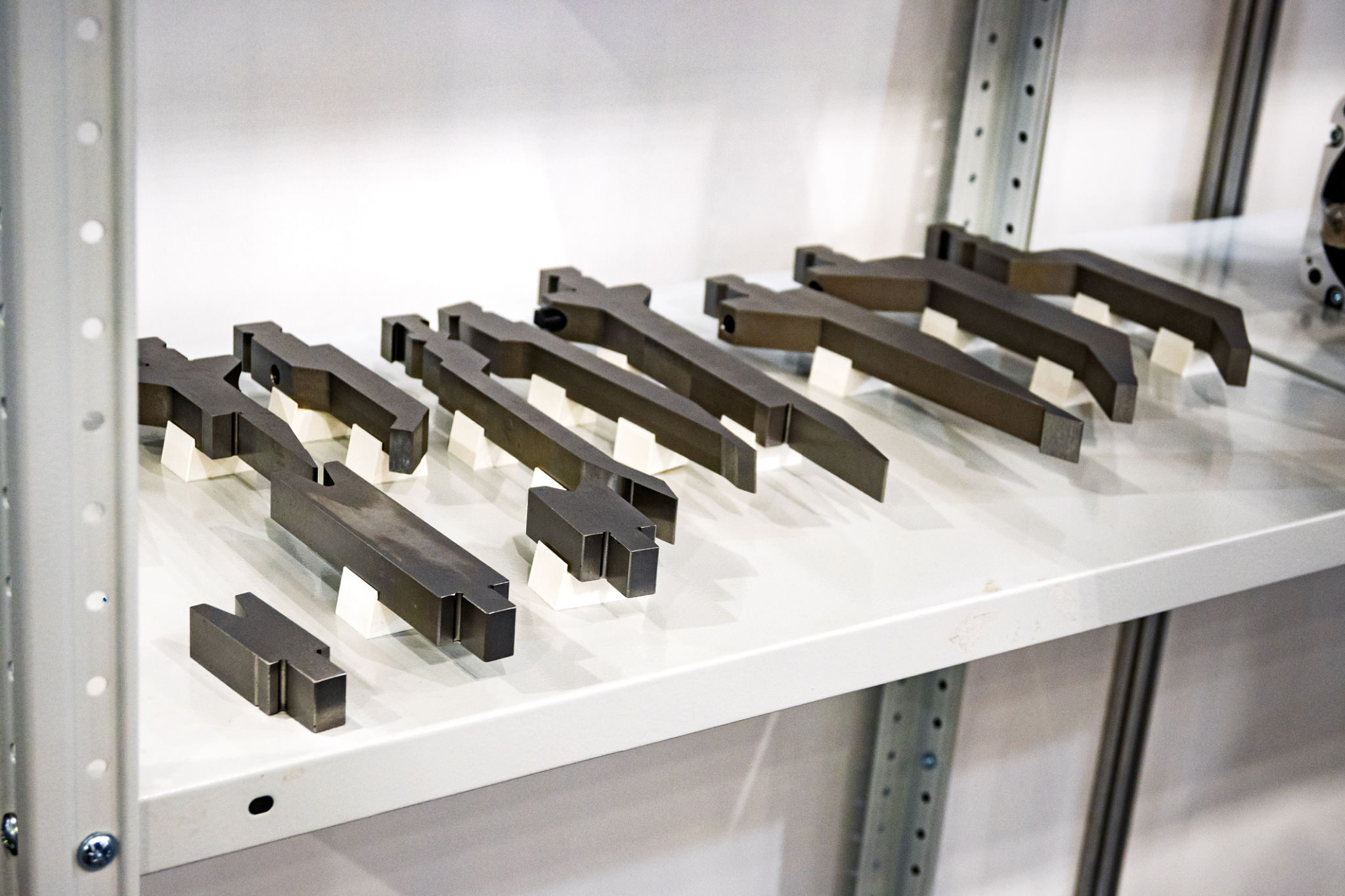

Precision stamping dies are indispensable tools in the automotive manufacturing industry. These dies are meticulously crafted to shape and cut metal sheets into specific components used in vehicles. The precision involved ensures that each part fits perfectly, contributing to the overall quality and safety of the automobile. The process of creating these dies is a blend of art and science, demanding both creativity and technical expertise.

The Role of Stamping Dies in Automotive Manufacturing

In the automotive sector, the use of precision stamping dies is crucial for producing parts that meet strict tolerances. These components range from tiny elements like clips and brackets to larger parts such as body panels. The accuracy of stamping dies ensures that each component is produced with consistent quality, which is vital for the assembly line process.

Moreover, precision stamping allows for high-volume production, which is essential to meet the demands of the automotive market. By utilizing state-of-the-art technology and materials, manufacturers can produce thousands of identical parts quickly and efficiently.

Types of Stamping Dies

There are several types of stamping dies used in automotive applications, each designed for specific tasks:

- Progressive Dies: These dies perform multiple operations in a single pass through the press, which enhances efficiency.

- Transfer Dies: Parts are manually or automatically transferred from one station to another, allowing for more complex shapes.

- Compound Dies: These are used for operations that require multiple cutting actions at once.

The Manufacturing Process

The manufacturing of precision stamping dies involves several steps, starting with design and ending with testing. The design phase uses CAD software to create detailed blueprints, ensuring accuracy and functionality. Following design, skilled machinists craft the dies using high-grade materials like tool steel, chosen for its durability and resistance to wear.

After initial creation, the dies undergo rigorous testing to ensure they meet specifications. This phase is crucial as it identifies any issues that could affect performance, allowing for adjustments before mass production begins.

Advancements in Stamping Die Technology

The field of stamping die technology is constantly evolving, with innovations aimed at improving efficiency and precision. Recent advancements include the integration of computer-aided manufacturing (CAM) systems and the use of simulation software to predict outcomes before physical production begins. These technologies not only reduce errors but also save time and resources.

The Importance of Precision in Stamping Dies

Precision is paramount in the world of automotive manufacturing. A small deviation in the dimensions of a part can lead to significant issues down the line, affecting everything from assembly to vehicle performance. Precision stamping dies ensure that every component meets exact specifications, contributing to the overall reliability and safety of vehicles.

This level of accuracy also helps manufacturers adhere to stringent regulatory standards, which are particularly important in the automotive industry where safety is a top priority.

The Future of Precision Stamping Dies

Looking ahead, the future of precision stamping dies appears promising with ongoing research and development. The focus is on increasing automation to further streamline production processes and enhance quality control. Additionally, sustainable practices are being incorporated to reduce waste and improve energy efficiency.

The evolving landscape of automotive technology will continue to drive innovations in precision stamping dies, ensuring they remain a critical component in vehicle manufacturing for years to come.