Expert Tips for Designing Molds for Outdoor Sports Equipment

Understanding the Basics of Mold Design

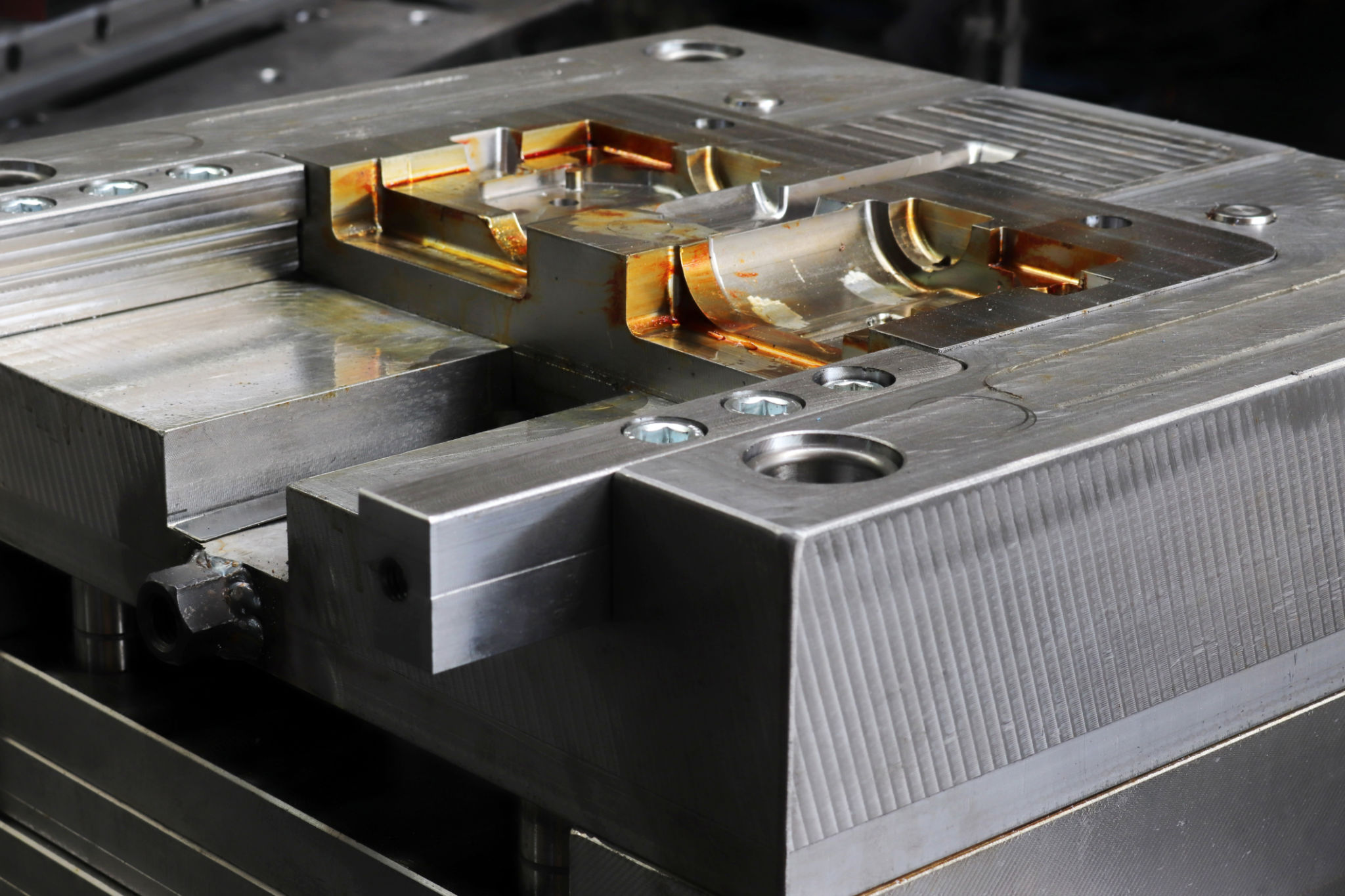

When it comes to designing molds for outdoor sports equipment, understanding the basics is crucial. Molds are essential in the manufacturing process, as they determine the shape and structure of the final product. They must be precise and durable to withstand repeated use and environmental factors. A well-designed mold ensures that each piece of sports equipment meets quality standards and performs effectively in outdoor conditions.

Material Selection for Molds

The choice of material for your mold is one of the most important decisions in the design process. Typically, steel and aluminum are popular choices because of their strength and durability. Steel molds offer high precision and longevity, making them ideal for high-volume production. Aluminum molds, on the other hand, are lighter and can be more cost-effective for smaller production runs. Choosing the right material impacts not only the cost but also the quality and lifespan of the mold.

Considering Environmental Factors

Molds designed for outdoor sports equipment must endure various environmental conditions. This includes exposure to sunlight, moisture, and temperature fluctuations. It's essential to consider these factors during the design phase to prevent warping, cracking, or other forms of deterioration. Implementing UV-resistant coatings or using corrosion-resistant materials can significantly extend the life of your molds.

Precision Engineering in Mold Design

Precision is key in mold design, especially for complex sports equipment with intricate details. Advanced computer-aided design (CAD) software can aid in creating precise mold designs, ensuring that every aspect is accurate down to the smallest detail. Using precision engineering techniques minimizes errors and defects in the manufacturing process, leading to higher quality products.

Testing and Prototyping

Before finalizing a mold design, it's crucial to test and prototype. Prototyping allows designers to identify potential issues and make necessary adjustments before full-scale production begins. This step helps in refining the design, ensuring that the final mold produces equipment that meets all functional requirements and safety standards.

Cost-Effectiveness and Efficiency

Designing molds with cost-effectiveness in mind can lead to significant savings over time. By optimizing the design to reduce material waste and streamline production processes, manufacturers can lower their costs while maintaining high quality. Using efficient design practices also reduces production time, allowing for faster turnaround and increased output.

Collaboration with Experts

Collaborating with experienced mold designers and engineers can greatly enhance the quality of your molds. These professionals bring valuable insights and innovative solutions to the design process, ensuring that the final product is both functional and durable. Investing in expert guidance can lead to superior product performance and customer satisfaction.

Continuous Improvement and Innovation

The world of outdoor sports equipment is constantly evolving, with new materials and technologies emerging regularly. Staying informed about these advancements and incorporating them into your mold design process is crucial for maintaining a competitive edge. Continuous improvement and innovation are key to producing high-quality sports equipment that meets the changing demands of consumers.