Expert Tips on Maintaining Your Injection Molds for Elderly Products

Understanding the Importance of Injection Mold Maintenance

Injection molds are critical in the production of products designed for the elderly, ensuring precision and quality. Proper maintenance of these molds not only extends their lifespan but also ensures the consistent quality of the products. This is especially important in items like mobility aids, hearing devices, and other essential products.

Regular maintenance can prevent costly repairs and downtime. By following expert advice, manufacturers can optimize their operations and ensure that their products meet the necessary safety and quality standards.

Regular Cleaning and Inspection

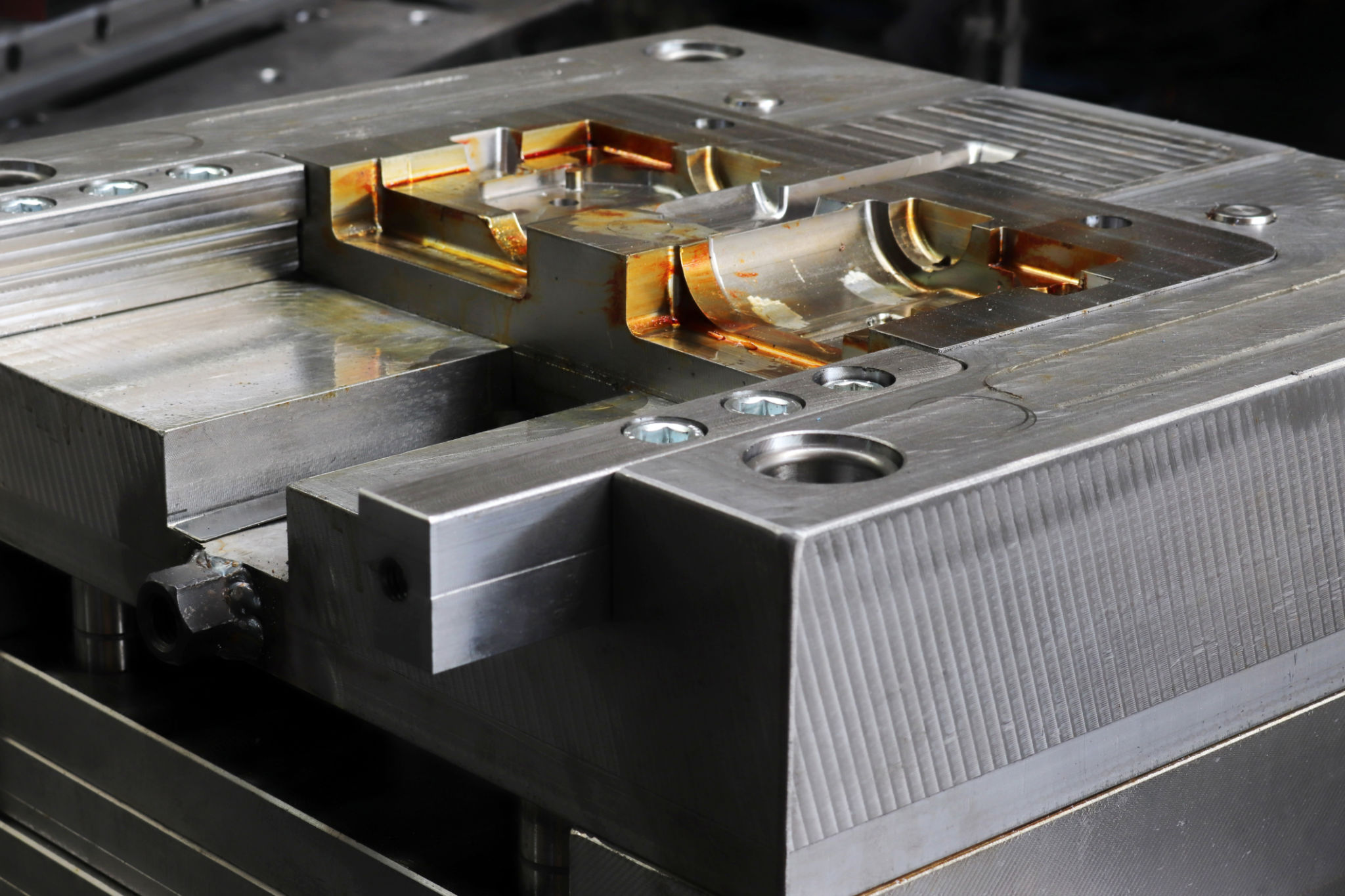

One of the primary steps in maintaining injection molds is to establish a routine cleaning schedule. This helps in removing any residue or buildup that might affect the mold's performance. A thorough inspection should also be conducted to identify any wear or damage.

During inspections, look for signs of corrosion, cracks, or any deformation. These issues can lead to defects in the final product, which is crucial to avoid, especially in products meant for the elderly.

Use of Non-Abrasive Cleaners

When cleaning the molds, use non-abrasive cleaners to prevent any damage to the mold's surface. Abrasive materials can lead to scratches and affect the mold's precision. It's essential to choose cleaners that are compatible with the mold material.

Proper Storage Techniques

Storing your injection molds correctly is vital in maintaining their condition. Always store molds in a clean, dry environment to prevent rust and corrosion. If possible, apply a protective coating to add an additional layer of protection.

Ensure that molds are stored in a way that prevents any physical damage. Proper shelving or storage containers can help in keeping molds safe and organized.

Temperature and Humidity Control

Controlling the temperature and humidity in the storage area is crucial. Extremes in temperature can cause the mold material to expand or contract, leading to potential damage. Maintaining a stable environment ensures the longevity of the molds.

Implementing a Predictive Maintenance Program

A predictive maintenance program can be highly effective in managing injection molds. This involves using technology to predict potential failures before they occur, allowing for proactive measures to be taken.

By analyzing data and trends, manufacturers can schedule maintenance activities at optimal times, preventing unexpected breakdowns and ensuring the continuous production of high-quality products for the elderly.

Training and Skill Development

Proper training for the maintenance team is essential. Ensuring that staff are skilled and knowledgeable about the latest maintenance techniques can significantly improve mold performance and longevity.

Investing in regular training sessions and workshops can keep the team updated on industry best practices and technological advancements.