How to Choose a Reliable Mold Manufacturer in China: A Comprehensive Guide

Understanding the Importance of a Reliable Mold Manufacturer

Choosing a reliable mold manufacturer in China is crucial for the success of your production project. The right manufacturer will ensure high-quality molds that can withstand rigorous usage while maintaining precision and durability. Given China’s dominant position in the manufacturing sector, finding the right partner is essential for cost-effectiveness and product quality.

The process of selecting a mold manufacturer involves various considerations, including technical expertise, production capabilities, and compliance with international standards. This guide aims to help you navigate these factors effectively to make an informed decision.

Research and Shortlist Potential Manufacturers

Start your search by researching potential manufacturers online. Platforms like Alibaba or Made-in-China offer access to numerous suppliers, but it's essential to perform due diligence. Look for companies with a good track record, positive reviews, and a comprehensive portfolio of past projects.

Once you have a list of potential candidates, narrow it down by considering their specialization. Some manufacturers focus on specific industries or types of molds, such as injection molds or blow molds, which can be crucial depending on your needs.

Evaluate Technical Expertise and Capabilities

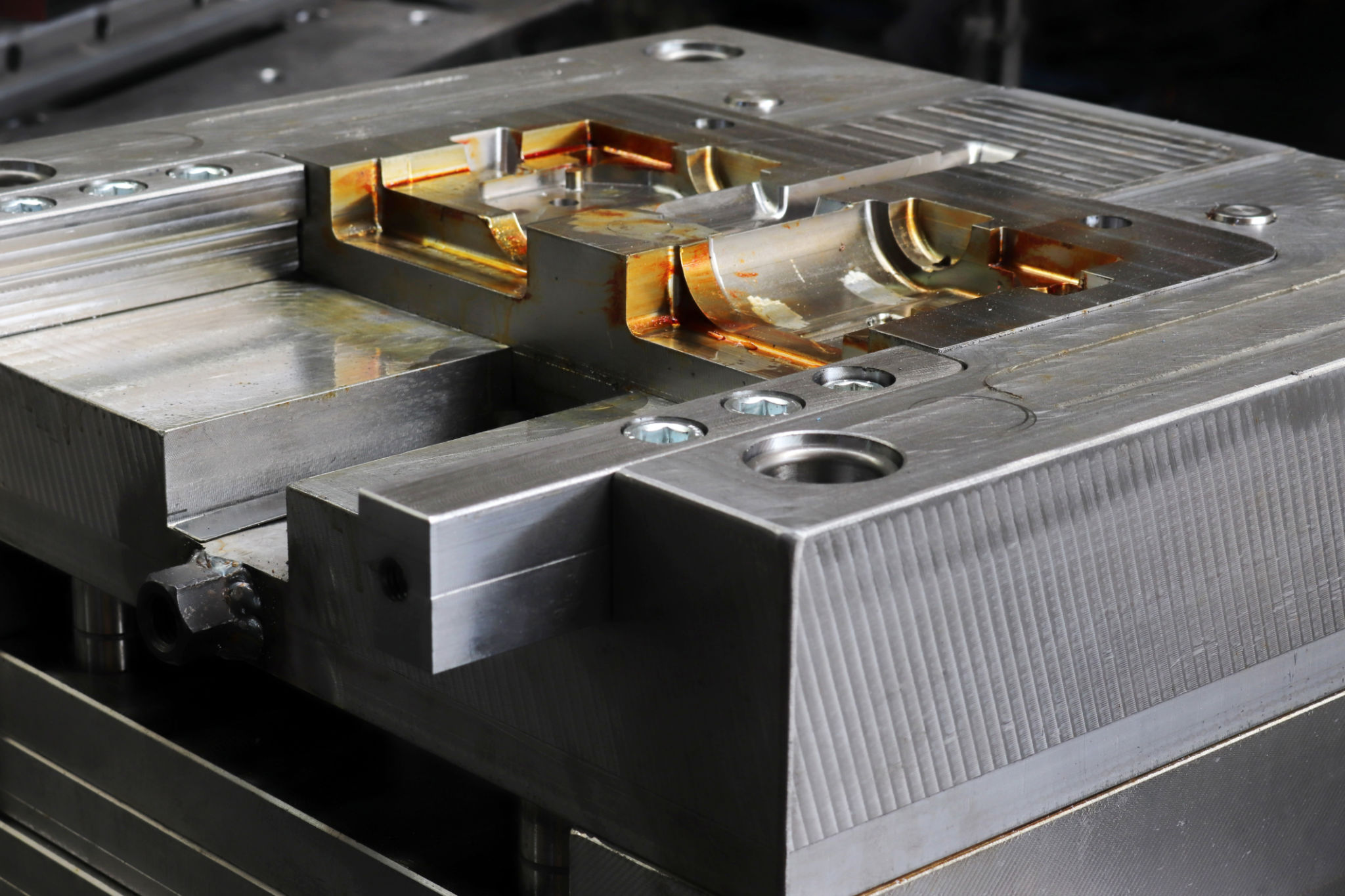

Technical expertise is a critical factor when choosing a mold manufacturer. Assess their engineering capabilities, design proficiency, and technology used in the manufacturing process. Manufacturers with state-of-the-art CNC machines and CAD/CAM software typically offer better precision and quality.

Additionally, inquire about their team’s qualifications and experience. A skilled team ensures that potential issues are addressed swiftly and efficiently, minimizing production delays and ensuring that the molds meet your specifications.

Assess Quality Assurance Processes

Quality assurance is paramount in mold manufacturing. Ensure that the manufacturer follows stringent quality control procedures throughout the production process. Check if they have ISO certifications or other relevant accreditations that demonstrate their commitment to quality.

Ask about their testing methods and how they ensure each mold meets the desired standards before delivery. A reliable manufacturer should provide detailed reports and be open to third-party inspections if necessary.

Consider Communication and Customer Service

Effective communication is essential when working with an overseas manufacturer. Evaluate their responsiveness and willingness to provide clarity on technical questions or concerns. Language barriers can pose challenges, so it’s beneficial if the manufacturer has English-speaking representatives.

Customer service also plays a significant role. A manufacturer committed to building a long-term partnership will prioritize your needs, provide timely updates, and address issues promptly.

Review Pricing and Payment Terms

While price should not be the sole deciding factor, it's still an important consideration. Obtain detailed quotes from shortlisted manufacturers and compare them. Be wary of prices that seem too good to be true, as they may result in compromised quality.

Discuss payment terms upfront. Many manufacturers require a deposit before starting production, with the balance due upon completion. Ensure you are comfortable with these terms before proceeding.

Visit the Manufacturer if Possible

If feasible, visiting the manufacturer can provide valuable insights into their operations. It allows you to assess their facilities, meet the team, and gain firsthand experience of their production processes.

This visit can also strengthen your relationship with the manufacturer, fostering trust and ensuring smoother collaboration in the future.