How to Choose the Right Automotive Injection Molds for Your Manufacturing Needs

Understanding Automotive Injection Molds

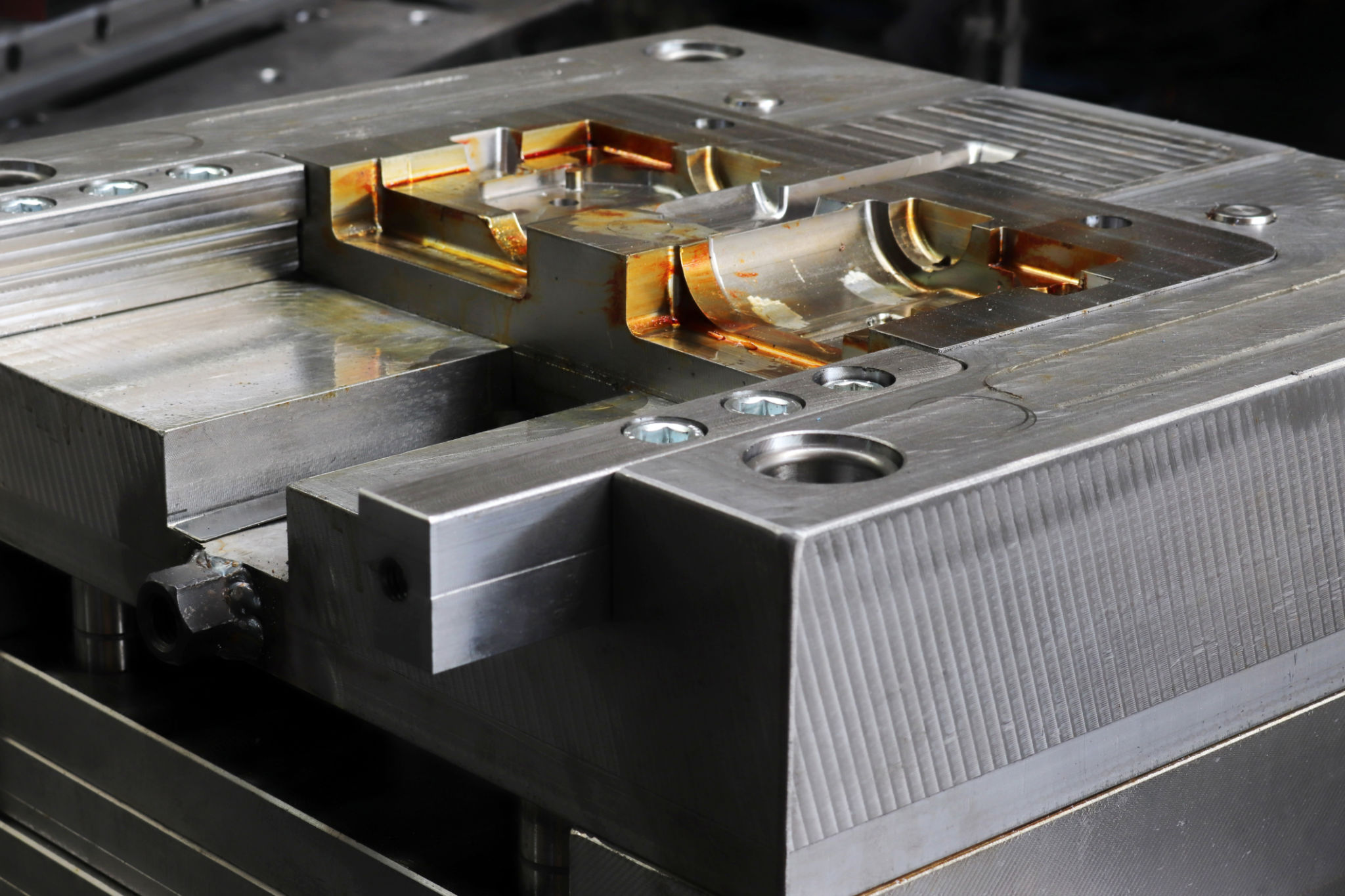

Automotive injection molds are essential tools in the manufacturing process of vehicle parts. These molds are used to shape and form plastics into various components, from dashboard panels to engine covers. Selecting the right mold is crucial for ensuring quality, efficiency, and cost-effectiveness in production. Here, we explore the key considerations for choosing the best automotive injection molds for your manufacturing needs.

Assessing Material Requirements

One of the first steps in selecting an injection mold is understanding the material requirements for your automotive parts. Different plastics require different mold configurations to achieve optimal results. Consider the type of plastic you need, such as ABS, polycarbonate, or polypropylene, and assess their properties like strength, flexibility, and temperature resistance. The mold must be compatible with these materials to ensure the final product meets performance standards.

Thermal Properties and Durability

The thermal properties of the mold material are vital for maintaining consistent quality during production. Choose molds that can withstand high temperatures without deforming or deteriorating. Additionally, durability is crucial; investing in a high-quality mold can reduce long-term costs by minimizing maintenance and replacement needs.

Precision and Complexity of Design

The design complexity of your automotive parts will influence your choice of injection molds. For intricate designs with fine details, precision molds are necessary to replicate each element accurately. Consider using molds with advanced features such as hot runner systems, which can enhance precision by controlling the flow of molten plastic more effectively.

Customization and Flexibility

In today’s competitive market, flexibility is a significant advantage. Opt for molds that offer customization options to adapt to evolving automotive design trends. This flexibility allows manufacturers to quickly respond to market demands and produce bespoke parts that meet customer specifications.

Evaluating Production Volume and Cost

The volume of production directly impacts the type of mold suitable for your needs. High-volume production requires molds that can endure repeated use without compromising quality. However, for low-volume or prototype production, less expensive molds may suffice. Evaluate your production goals and budget constraints to determine the most cost-effective solution.

Consideration of Maintenance Needs

Regular maintenance is key to extending the lifespan of your injection molds. Choose molds that are easy to maintain and clean, reducing downtime and ensuring uninterrupted production schedules. Consider partnering with a supplier that offers support services for maintenance and repairs.

Supplier Reputation and Support

Lastly, the reputation and support services provided by the mold supplier play a critical role in your decision-making process. Research potential suppliers by reviewing their track record, customer testimonials, and after-sales support options. A reliable supplier will offer guidance throughout the mold selection process and provide ongoing assistance as needed.

By carefully considering these factors, you can select the right automotive injection molds that align with your manufacturing objectives, ensuring efficiency, quality, and profitability in your production line.