How to Maintain High-Performance Injection Molds for Optimal Results

Understanding the Importance of Injection Mold Maintenance

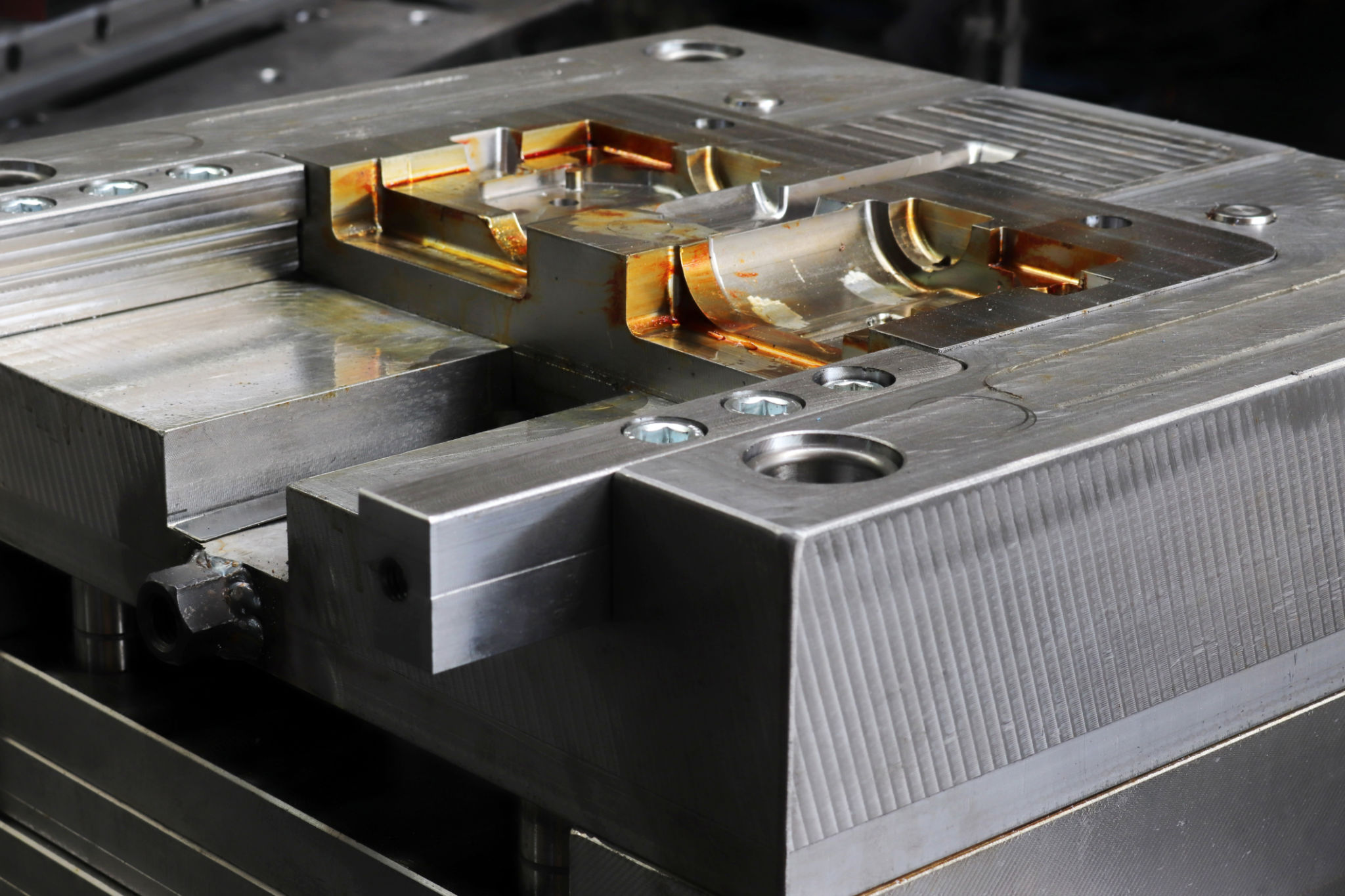

Injection molds are critical components in the manufacturing process, ensuring the production of high-quality plastic parts. Proper maintenance is vital to prolong their lifespan and maintain optimal performance. Regular upkeep not only prevents costly repairs but also ensures consistent quality in the products produced.

Regular Inspection and Cleaning

One of the fundamental steps in maintaining injection molds is conducting regular inspections. This involves checking for signs of wear and tear, such as cracks or corrosion, which can affect the mold's efficiency. Cleaning is equally important; any remnants of plastic material or debris should be removed to prevent defects in future production runs.

Use appropriate cleaning agents that do not damage the mold surface. Avoid abrasive materials that could scratch or damage the mold, reducing its effectiveness over time.

Lubrication and Proper Storage

Lubrication plays a crucial role in ensuring smooth operation. Apply suitable lubricants to all moving parts, such as guide pins and bushings, to minimize friction and wear. This not only enhances performance but also extends the mold's life.

Proper storage is another key aspect of mold maintenance. When not in use, molds should be stored in a dry, clean environment to prevent rust and contamination. Using protective covers helps shield them from dust and environmental factors that could cause deterioration.

Implementing a Preventive Maintenance Schedule

Establishing a preventive maintenance schedule is essential for keeping injection molds in top condition. This involves setting regular intervals for inspections, cleaning, lubrication, and testing. A well-planned schedule ensures that minor issues are addressed before they escalate into major problems.

- Daily checks for visible signs of damage or residue build-up.

- Weekly cleaning and inspection of essential components.

- Monthly comprehensive assessments, including testing for functionality.

Training Personnel for Effective Maintenance

The effectiveness of a maintenance program largely depends on the skill and knowledge of the personnel involved. Training employees in proper maintenance techniques is crucial. This includes understanding the specific requirements of different molds and recognizing early warning signs of potential issues.

Encouraging a culture of proactive maintenance among staff ensures that everyone is committed to preserving the integrity and performance of the molds.

Utilizing Advanced Monitoring Technology

Advancements in technology have introduced sophisticated monitoring tools that can significantly enhance mold maintenance practices. Sensors and software solutions can provide real-time data on mold conditions, alerting operators to irregularities before they become problematic.

Implementing these technologies can lead to more efficient maintenance routines, reducing downtime and increasing overall productivity.

Conclusion

Maintaining high-performance injection molds requires a combination of regular inspection, cleaning, lubrication, and strategic scheduling. By investing in training and utilizing advanced technologies, manufacturers can ensure their molds operate at peak efficiency, leading to better product quality and reduced operational costs. Proactive maintenance not only extends the life of injection molds but also optimizes production outcomes.