Innovations in Mold Crafting for Electronics: A Look at Emerging Trends

Revolutionizing Mold Crafting in Electronics

The electronics industry is rapidly advancing, and with it, the techniques and technologies used in mold crafting are evolving. These innovations are crucial for improving the manufacturing process, enhancing product quality, and reducing costs. As such, staying informed about the latest trends in mold crafting for electronics is essential for industry professionals.

Recent developments in mold crafting have focused on precision, efficiency, and sustainability. These innovations are pivotal for meeting the growing demands of the electronics market, where miniaturization and increased functionality are key drivers.

Precision Engineering: The Future of Mold Crafting

One of the most significant trends in mold crafting for electronics is the shift towards precision engineering. As electronic devices become smaller and more complex, the molds used to create their components must be incredibly accurate. Advanced computer-aided design (CAD) software and computer-aided manufacturing (CAM) systems are now standard tools in the mold crafting process. These technologies allow for intricate designs that were previously unattainable.

Additionally, the use of high-precision machining techniques, such as laser cutting and electrical discharge machining (EDM), has become more prevalent. These methods enable manufacturers to create molds with extremely tight tolerances, ensuring that each component fits perfectly within the larger assembly.

Efficient Production: Embracing Automation

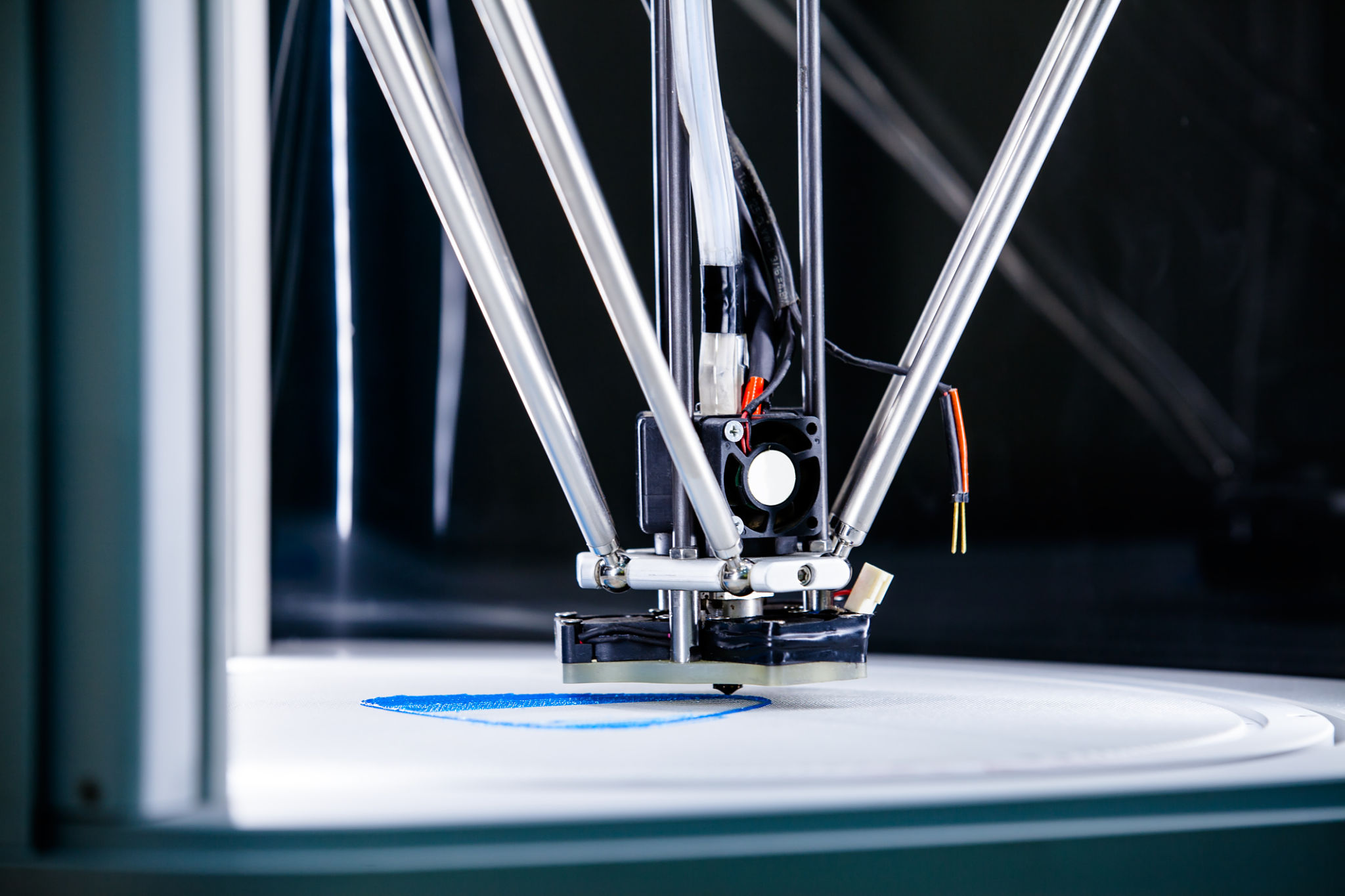

Automation is another critical trend reshaping the landscape of mold crafting for electronics. Automated systems not only enhance production speed but also improve consistency and reduce human error. This shift towards automation is facilitated by advancements in robotics and artificial intelligence (AI), which allow for seamless integration into existing manufacturing processes.

Incorporating automation in mold crafting results in faster turnaround times and increased production capacity. Moreover, it enables manufacturers to respond swiftly to changes in market demand, providing a competitive edge in a rapidly evolving industry.

Sustainable Practices: Eco-Friendly Innovations

Sustainability is becoming increasingly important in all facets of manufacturing, and mold crafting for electronics is no exception. Emerging trends focus on reducing waste and energy consumption while utilizing eco-friendly materials. For instance, manufacturers are exploring the use of biodegradable materials and recycled plastics for mold creation.

Moreover, energy-efficient machines and processes are being adopted to lower the carbon footprint of mold crafting operations. These sustainable practices not only help protect the environment but also appeal to environmentally conscious consumers who prioritize green products.

Material Science: Advancements in Mold Materials

The development of new materials is also playing a significant role in the evolution of mold crafting for electronics. High-performance polymers and composite materials are increasingly used to create molds that can withstand extreme temperatures and pressures. These materials offer enhanced durability and longevity, reducing the need for frequent replacements.

Additionally, advancements in nanotechnology are paving the way for even more innovative materials that can enhance the properties of molds, such as improved thermal conductivity or electrical insulation.

Conclusion

The innovations in mold crafting for electronics are transforming the industry by enhancing precision, efficiency, and sustainability. As these trends continue to evolve, manufacturers must stay informed to remain competitive and meet the demands of a rapidly changing market. By embracing these emerging technologies and practices, companies can ensure they are well-equipped to face the challenges of tomorrow's electronics landscape.