Hands-Free Efficiency: Why Field Engineers Are Adding Phone Mounts to Industrial Equipment

Hands-Free Efficiency: Why Field Engineers Are Adding Phone Mounts to Industrial Equipment

In fast-paced industrial environments, every second counts—and every hand matters.

Field engineers, maintenance technicians, and equipment operators often find themselves juggling multiple tasks at once. One hand might be adjusting a valve or holding a tool, while the other is trying to keep a smartphone steady to monitor a diagnostic app or follow step-by-step repair instructions. The result? Frustration, inefficiency, and in some cases, even safety hazards.

That’s why hands-free mobile solutions, such as rugged phone mounts, are quietly becoming an essential part of modern industrial equipment design. These simple devices are transforming the way technicians and engineers operate, ensuring that their phones remain secure while they focus on their tasks.

A Real-World Use Case

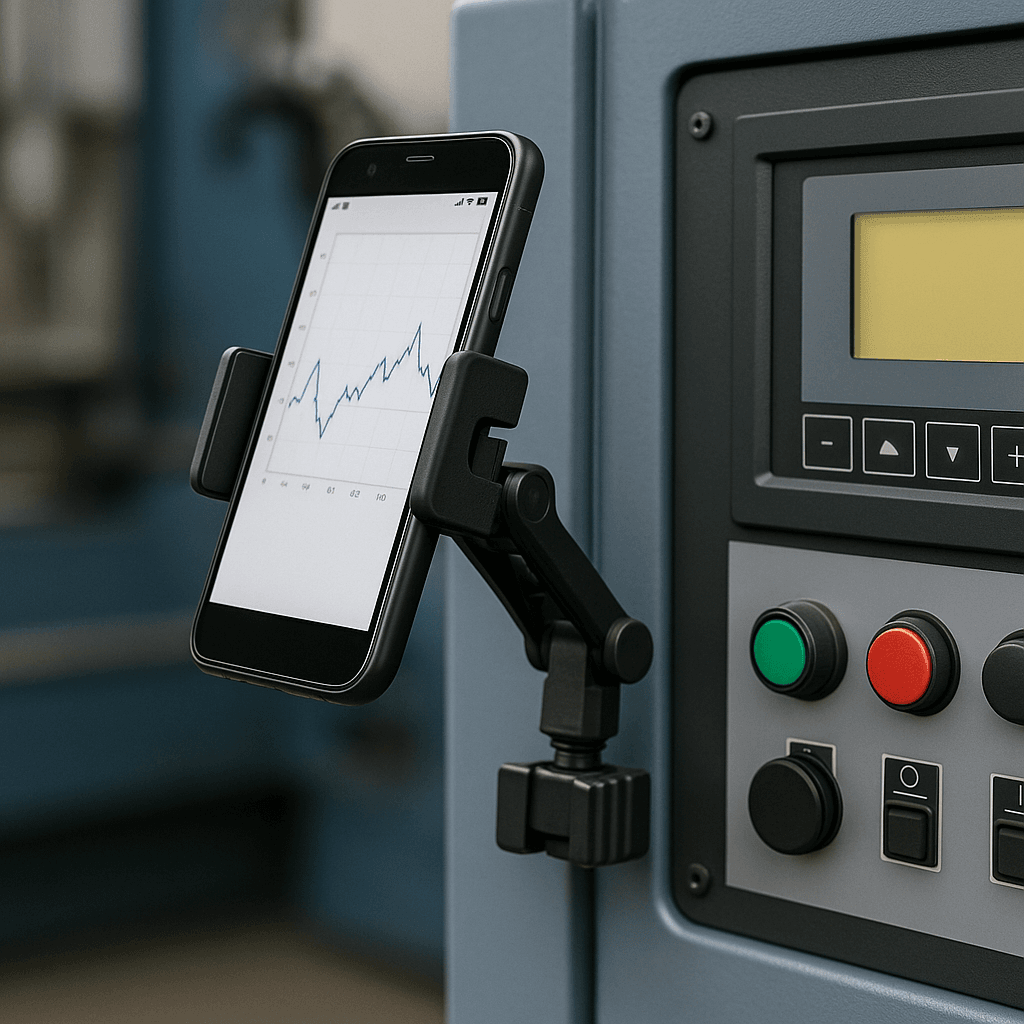

Imagine a technician performing a calibration on-site, needing to read live sensor data via a Bluetooth-connected app. Without a stable way to position their phone, they risk dropping it—or worse, misreading data while struggling to hold everything in place.

A simple, custom phone mount installed on the control panel or nearby surface changes the game entirely. Now the technician can operate with both hands while still viewing critical information at a glance. With these hands-free phone holders, industrial teams can work more efficiently, without distractions.

Why Industrial Teams Are Investing in Phone Mounts

Efficiency Boost: A heavy-duty phone holder reduces task time by keeping information accessible and hands-free, making technicians more productive. It’s not just a simple accessory—it's a productivity tool.

Operator Safety: In environments with hazardous equipment or in fieldwork settings, minimizing distractions is critical. A phone mount helps avoid phone drops in sensitive work zones, ensuring the safety of the operator while maintaining smooth operations.

Standardization: More OEMs and facilities are integrating phone holders as part of their industrial equipment specifications. Whether it's a panel-mounted phone holder or a magnetic phone mount, having these options standard in equipment designs is becoming a key trend.

Customization Options: Every industrial environment is unique, and so are the devices technicians use. Custom mounting solutions tailored to specific devices, environments, and mounting points allow for seamless integration into existing workflows. Whether you need a clamp-based phone holder or a more flexible, adjustable solution, these mounts can be adapted to fit any scenario.

What to Look for in a B2B Phone Mount Supplier

If you’re sourcing phone mounts for industrial applications, it’s not just about the phone—it’s about fit, durability, and integration. Look for suppliers who offer:

Custom mounting solutions (panel-mounted, magnetic, or clamp-based)

Materials that withstand heat, oil, and vibration—perfect for heavy-duty use in industrial environments

Easy installation for retrofit or OEM integration

Experience working with field engineers and product managers to develop mounts that fit seamlessly into your workflow

We Build With the Operator in Mind

At HXP Mold, we specialize in OEM/ODM phone mount solutions for industrial use. From custom tooling to large-scale injection molding, we collaborate directly with product managers and engineers to develop mounts that integrate seamlessly into your workflow.

Whether you're outfitting control systems, test benches, or mobile diagnostics stations, we’re here to help design, prototype, and manufacture a mount that works just as hard as your team does.

Let’s Build Something Hands-Free Together

Have a specific application in mind? Just hit reply or reach out—we’d love to learn more about your equipment and help you bring the perfect phone mount to life.

We turn small parts into big usability upgrades.

Just send us your idea. We’ll take it from there.

🌐 hxpmold.com

📨 [email protected]