Sourcing Injection Molds in China: A Comprehensive Guide for Global Buyers

Understanding the Injection Mold Market in China

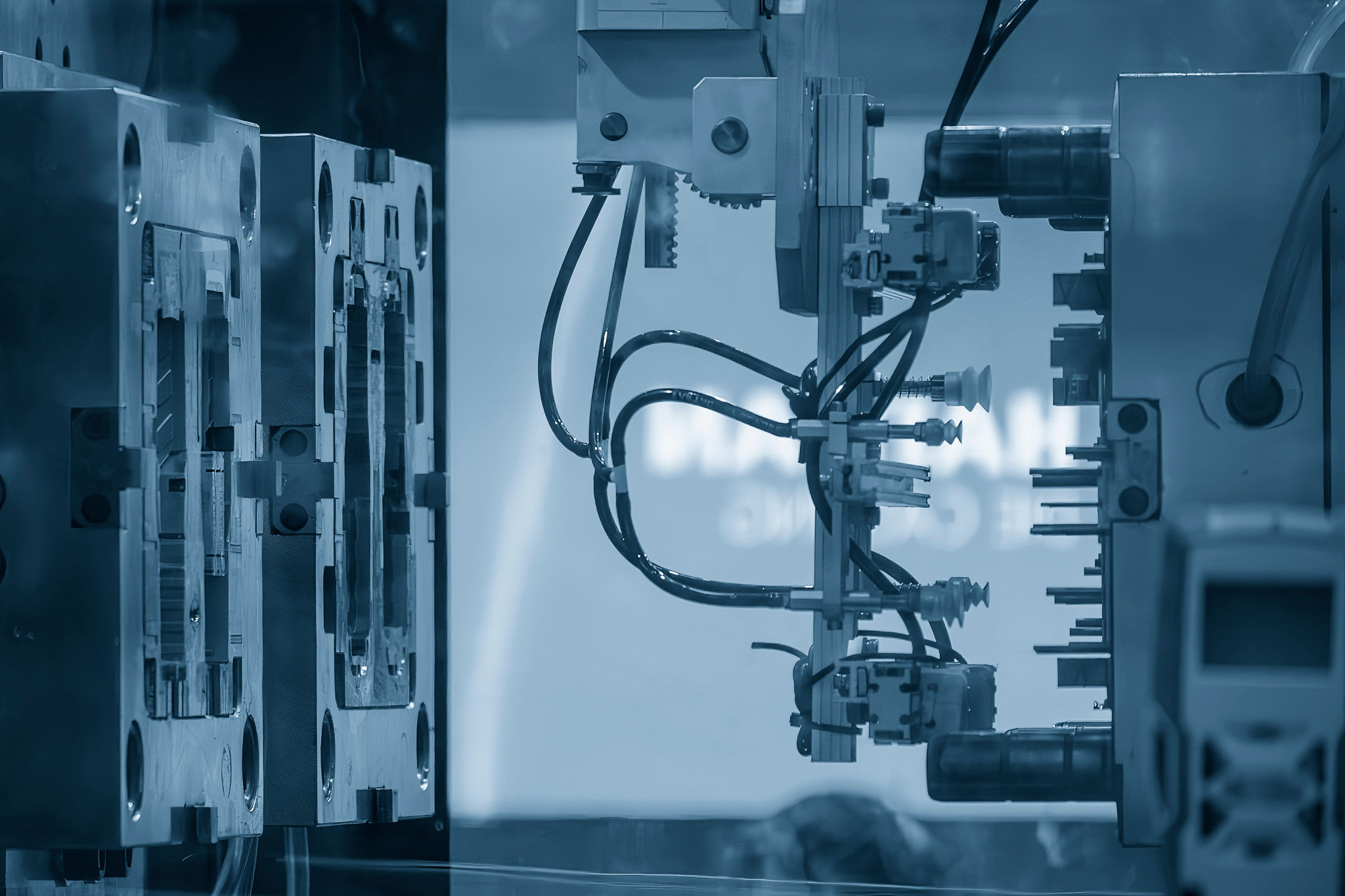

The global manufacturing landscape is constantly evolving, and China stands at the forefront as a leading supplier of injection molds. With its vast industrial base and competitive pricing, sourcing injection molds from China has become an attractive option for businesses worldwide. However, navigating this market requires a strategic approach to ensure quality and cost-effectiveness.

China's injection mold industry offers a wide range of options, from simple molds to highly complex multi-cavity designs. The country's manufacturing hubs, predominantly located in provinces like Guangdong and Zhejiang, host a plethora of suppliers. It is crucial to understand the differences in capabilities and specializations among these manufacturers to find the right fit for your project needs.

Key Considerations When Sourcing Injection Molds

When sourcing injection molds in China, several key factors must be considered. First and foremost is the quality of the molds. Ensuring the supplier adheres to international quality standards such as ISO is essential to prevent costly errors and production delays. Additionally, evaluating a manufacturer's experience and expertise in your specific industry can provide insights into their capability to meet your requirements.

Another critical factor is the cost. While China is known for its competitive pricing, it's important to conduct a thorough cost analysis, including shipping and potential tariffs. Comparing quotes from multiple suppliers will give a clearer picture of the market rate and help in negotiating better terms. Remember, the lowest price does not always guarantee the best value.

Supplier Verification and Communication

Supplier verification is a vital step in the sourcing process. Conducting due diligence by checking the supplier's business license, certifications, and customer reviews can mitigate risks. Additionally, visiting the factory or hiring a third-party inspection service can provide firsthand insights into their production capabilities and quality control processes.

Effective communication is also paramount. Language barriers can pose challenges, so working with suppliers who have English-speaking representatives can facilitate smoother interactions. Clear communication about specifications, lead times, and payment terms will help in fostering a successful business relationship.

Logistics and Supply Chain Management

Managing logistics efficiently is crucial when sourcing from overseas. Partnering with experienced freight forwarders can ease the complexities of international shipping, including customs clearance and documentation. Understanding the nuances of Incoterms will also aid in determining responsibilities between buyer and seller during transit.

Furthermore, implementing robust supply chain management practices ensures timely delivery and reduces potential disruptions. Establishing clear timelines and maintaining regular communication with your supplier can help in anticipating and resolving any logistical challenges that may arise.

Leveraging Technology for Better Outcomes

The use of technology plays a significant role in optimizing the sourcing process. Platforms that offer digital quality inspections, real-time tracking, and virtual factory tours can enhance transparency and decision-making. Leveraging such tools can provide peace of mind and improve efficiency in managing overseas suppliers.

Additionally, utilizing project management software can streamline coordination between your team and suppliers, ensuring that all parties are aligned on project goals and timelines. This technological integration can be a game-changer in achieving successful outcomes when sourcing injection molds from China.

Building Long-Term Partnerships

Sourcing injection molds from China is not just a one-time transaction but an opportunity to build long-term partnerships. Developing strong relationships with reliable suppliers can lead to better pricing, improved quality, and priority service over time. Fostering trust and collaboration will create a win-win scenario for both parties involved.

In conclusion, sourcing injection molds in China offers immense potential for global buyers looking for quality and cost-effective solutions. By conducting thorough research, verifying suppliers, managing logistics efficiently, and leveraging technology, businesses can unlock significant value in their supply chain operations.