The Art of Customized Plastic Injection Molding in China

Understanding Plastic Injection Molding

Plastic injection molding is a highly versatile manufacturing process used to produce a vast array of plastic parts and products. This method involves injecting molten plastic into a mold cavity, where it cools and solidifies into the desired shape. In China, plastic injection molding has become a cornerstone of modern manufacturing due to its efficiency and ability to create complex and precise components.

One of the key advantages of plastic injection molding is its ability to produce large volumes of parts with high precision and consistency. This makes it ideal for industries ranging from automotive to consumer electronics. The process allows for the creation of intricate designs and offers flexibility in terms of materials used, including thermoplastics and thermosetting polymers.

The Rise of Customized Solutions

In recent years, there has been a significant shift towards customized plastic injection molding in China. Businesses are increasingly seeking tailor-made solutions that meet their specific needs, rather than opting for generic, off-the-shelf products. This trend is driven by the desire to enhance product functionality, improve aesthetic appeal, and differentiate from competitors.

Customized plastic injection molding allows manufacturers to work closely with clients to develop unique designs and specifications. This collaborative approach ensures that the end product aligns perfectly with the client’s vision and functional requirements. By leveraging advanced technology and skilled craftsmanship, Chinese manufacturers are able to offer bespoke solutions that cater to various industries.

Benefits of Customization

The benefits of customized plastic injection molding are manifold. Firstly, it enables businesses to create products that are tailored to their specific applications, leading to improved performance and customer satisfaction. Secondly, customization allows for greater design flexibility, enabling the incorporation of unique features and branding elements.

Moreover, customized solutions often result in more efficient production processes. By optimizing mold design and material selection, manufacturers can reduce waste and minimize production costs. This not only leads to cost savings but also aligns with sustainable manufacturing practices, which are becoming increasingly important in today's environmentally conscious market.

Challenges and Innovations

Despite its advantages, customized plastic injection molding is not without challenges. The process requires meticulous planning and precise execution to ensure that the final product meets the desired specifications. Additionally, the initial setup costs for custom molds can be high, although these costs are often offset by the long-term benefits of tailored solutions.

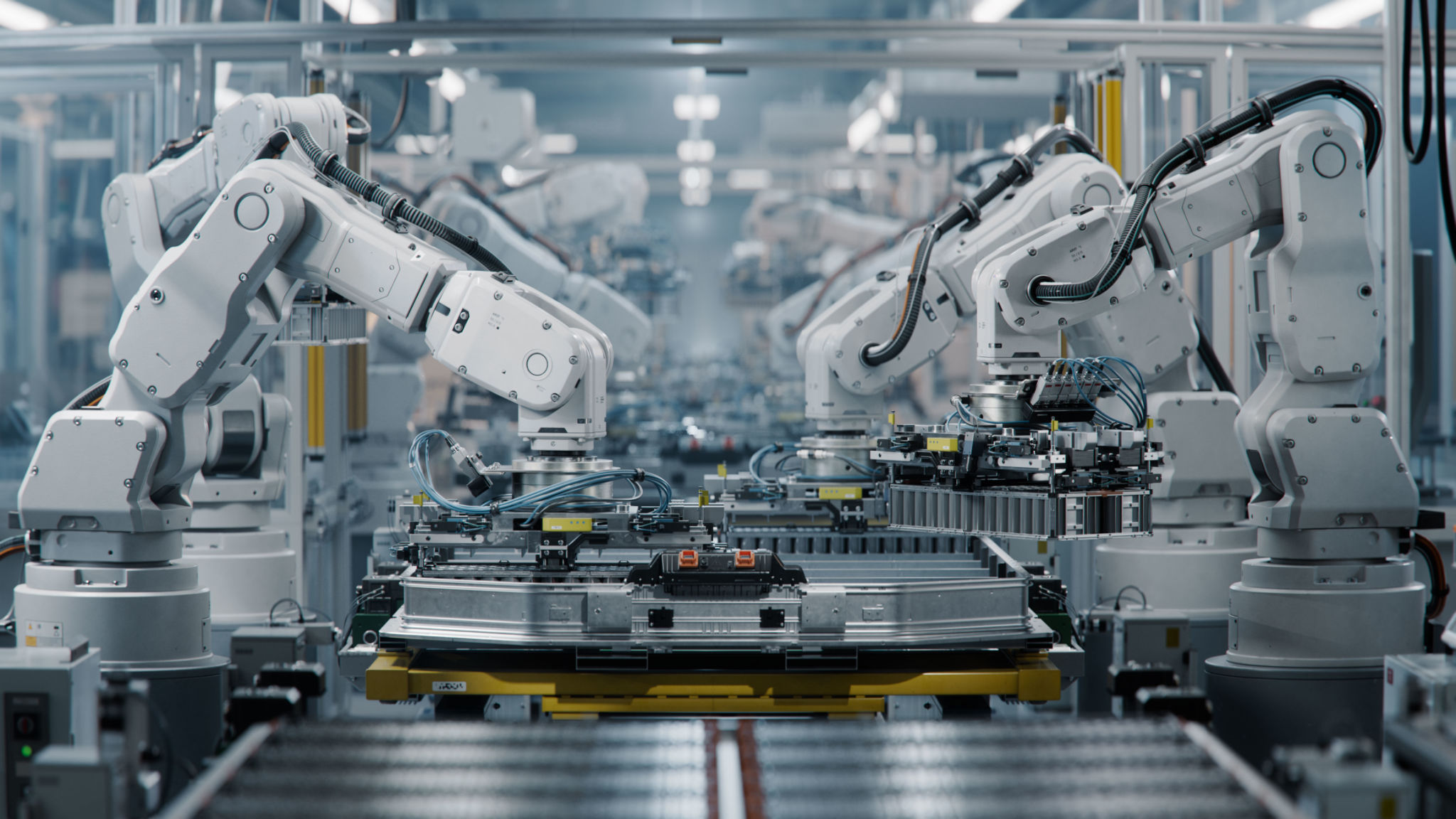

To address these challenges, Chinese manufacturers are embracing innovative technologies such as computer-aided design (CAD) and simulation software. These tools enable designers to visualize and test products before actual production, reducing the risk of errors and costly modifications. Furthermore, advancements in automation and robotics have enhanced production speed and accuracy, further solidifying China's position as a leader in customized plastic injection molding.

Choosing the Right Partner

For businesses looking to leverage the benefits of customized plastic injection molding in China, choosing the right manufacturing partner is crucial. It is important to select a provider with a proven track record of delivering high-quality custom solutions. Consider factors such as technical expertise, industry experience, and customer service when making your decision.

Collaborating with a reputable manufacturer can make a significant difference in the success of your project. A reliable partner will not only deliver superior products but also provide valuable insights and support throughout the entire production process. By working together with a skilled team, businesses can achieve their goals and bring innovative products to market.

The Future of Injection Molding in China

As technology continues to evolve, the future of customized plastic injection molding in China looks promising. Emerging trends such as smart manufacturing, 3D printing integration, and sustainable materials are poised to reshape the industry. These advancements will enable manufacturers to offer even more sophisticated and eco-friendly solutions.

In conclusion, the art of customized plastic injection molding in China is an essential component of modern manufacturing. By embracing innovation and focusing on quality, Chinese manufacturers are well-positioned to meet the growing demand for bespoke solutions across various sectors. As businesses continue to seek differentiation through customization, the industry will undoubtedly experience further growth and transformation.