Top Questions Answered: High-Performance Injection Molds for Electronics

Understanding High-Performance Injection Molds

In the electronics industry, high-performance injection molds play a crucial role in manufacturing precision components. These molds are designed to handle complex designs and high volumes, ensuring that each part meets stringent quality standards. But what exactly makes an injection mold "high-performance"? Let's delve into the details.

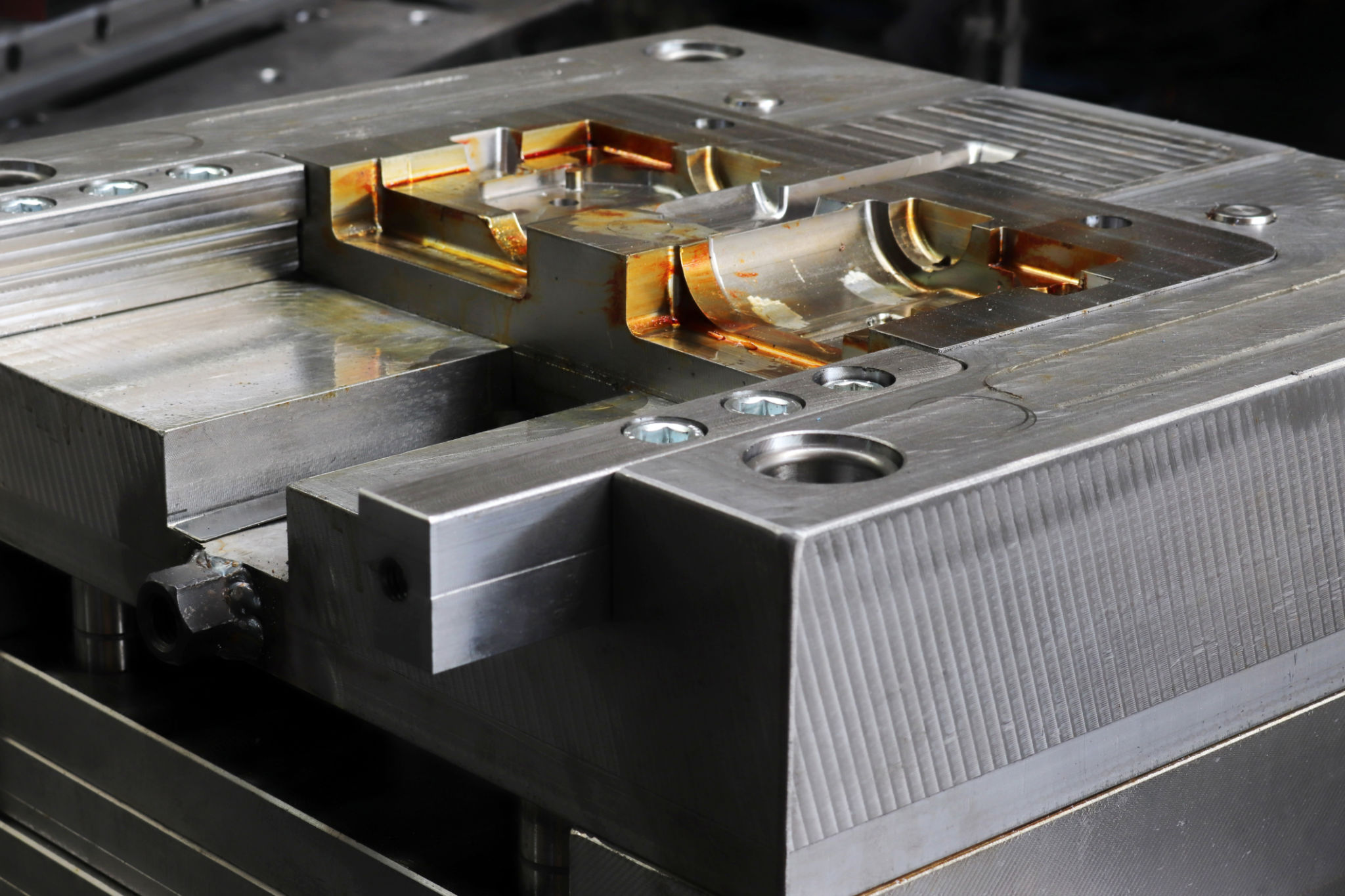

High-performance injection molds are crafted using advanced materials and techniques to withstand the demands of large-scale production. They offer precision, durability, and efficiency, making them ideal for electronics where intricate parts are common. Key materials used include hardened steel and aluminum, chosen for their strength and longevity.

How Do Injection Molds Benefit the Electronics Industry?

The benefits of using high-performance injection molds in electronics are numerous. First and foremost, they provide consistency in production. Each electronic component produced is identical, which is crucial for maintaining quality across devices.

Moreover, these molds significantly reduce production time. With their ability to produce thousands of parts swiftly, manufacturers can meet high demand without compromising on quality. This efficiency translates into cost savings and a faster time-to-market for new products.

Common Questions About Injection Molds

What Are the Typical Lifespans of These Molds?

The lifespan of high-performance injection molds varies based on material and usage. Typically, molds made from hardened steel can last for over a million cycles, while those made from aluminum may offer fewer cycles but are often more cost-effective for short runs.

How Are Injection Molds Maintained?

Regular maintenance is crucial to maximize the lifespan of injection molds. This involves cleaning, inspecting for wear and tear, and performing necessary repairs. Proper maintenance ensures that the molds function efficiently and continue to produce high-quality parts.

Choosing the Right Injection Mold Supplier

Selecting the right supplier is vital for ensuring the quality of your electronic components. Consider suppliers with a proven track record in the electronics sector and those who offer custom solutions tailored to your specific needs.

Additionally, look for suppliers who provide comprehensive support services, including design assistance and ongoing technical support. This partnership can greatly enhance your production capabilities and product quality.

Future Trends in Injection Molding for Electronics

As technology evolves, so do the demands on injection molding processes. The future of injection molds in electronics will likely see greater integration of automation and smart technologies. These advancements will further enhance precision and efficiency.

Furthermore, sustainable practices are becoming more prevalent. The industry is seeing a shift towards environmentally friendly materials and processes, aligning with global sustainability goals.

In conclusion, high-performance injection molds are integral to the electronics industry, offering reliability and efficiency. By understanding their benefits and maintenance, manufacturers can leverage these tools to produce top-quality electronic components consistently.