Top Trends in Die Casting for Household Products

Introduction to Die Casting in Household Products

Die casting has become a pivotal process in manufacturing a wide range of household products, thanks to its efficiency and precision. This method involves forcing molten metal under high pressure into a mold cavity, creating durable and intricate components. As technology advances, so does the evolution of die casting techniques. Let's delve into the top trends currently shaping this industry.

Advancements in Material Usage

One of the most significant trends in die casting is the development of new materials. Traditionally, materials like aluminum and zinc have been the mainstays of the process. However, innovations have led to the use of materials such as magnesium and various alloys that offer enhanced strength and reduced weight. These materials are increasingly used to produce everyday household items like faucets, cookware, and decorative hardware.

Benefits of New Materials

The introduction of these advanced materials brings several benefits, including improved thermal conductivity and corrosion resistance. This means that products are not only more robust but also longer-lasting, providing better value for consumers. Additionally, using lightweight materials contributes to energy efficiency in product use and transport.

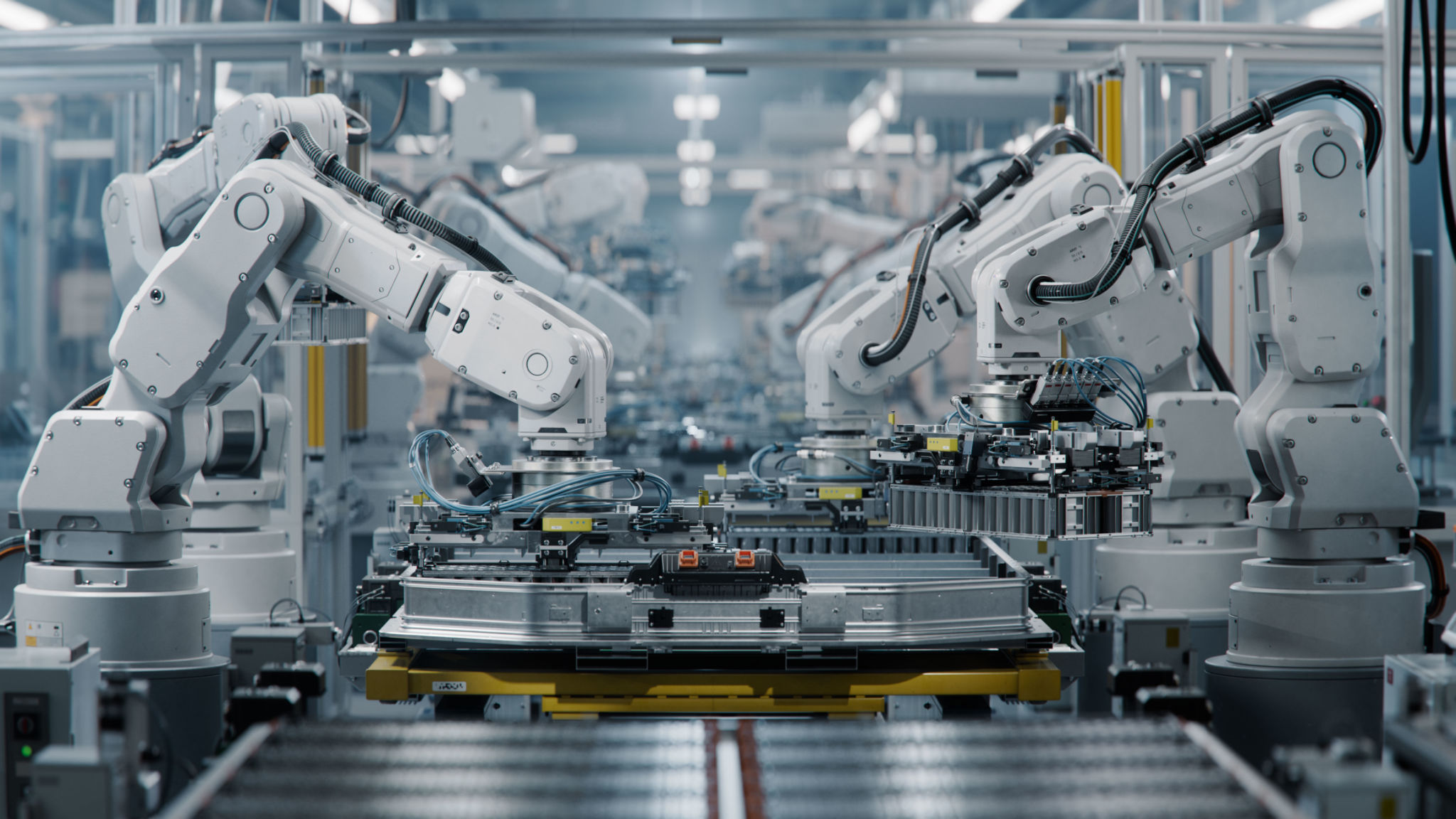

Automation and Smart Manufacturing

Automation is revolutionizing die casting operations. The integration of robotics and AI into manufacturing processes is reducing labor costs and improving precision. Smart manufacturing allows for real-time monitoring and control, ensuring consistent quality across batches of products. This trend is particularly important for household products where uniformity is key.

Impact on Production Efficiency

The use of automated systems minimizes human error and accelerates production timelines. Manufacturers can now produce more intricate designs at a fraction of the time previously required. This efficiency not only meets growing consumer demand but also reduces the environmental impact by minimizing waste.

Sustainability in Die Casting

Sustainability is becoming a central focus in die casting for household products. Manufacturers are adopting eco-friendly practices, such as recycling scrap material and using non-toxic coatings. This shift aligns with the global push towards reducing carbon footprints and promoting environmentally responsible production methods.

Recycling and Waste Reduction

By reusing excess metal from the die casting process, companies are reducing waste significantly. This practice not only conserves resources but also reduces costs associated with raw material procurement. As consumers increasingly value sustainability, these practices enhance brand reputation and customer loyalty.

Future Outlook

Looking ahead, the die casting industry is poised for continued growth and innovation. As technology advances, we can expect further improvements in efficiency, material science, and environmental responsibility. For household product manufacturers, keeping pace with these trends will be crucial in delivering high-quality, durable, and sustainable products to consumers.

In conclusion, the current trends in die casting are reshaping the landscape of household product manufacturing. By embracing new materials, automation, and sustainable practices, manufacturers can produce superior products that meet the demands of modern consumers.